BLOG.

‘The Bug’ Handmade Oak Living Room Furniture: Hugh’s Photo Diary

28th April 2012

Before I started this blog, I completed a number of projects where I took lots of photos during making. As I’m still on with casement windows at the moment, I thought I’d do another retrospective photo diary. This week, it’s ‘The Bug’ Oak living room Furniture. I completed the project in August last year, and it was published on bookcaseporn.com in January.

The clients heard about my work through someone I’d made a piece for 6 months earlier, and they came along to my workshop-warming party in January 2011 (the next workshop open day is on the 10th June 2012, and all are welcome). The clients wanted a contemporary piece of fitted furniture for their living room which would provide storage for all their media equipment. They had young children, and so were also in need of lots of space for toys and books, as well as some high cabinets which were out of reach to small hands.

Key design points were that they wanted lacquered cabinet fronts as a nod to their kitchen cabinet doors, natural timber for the body of the piece, and a bit of a ‘wow factor’. The concept for the design was inspired by those bug radios – contemporary, but also retro and playful. The cabinet’s would be formed from a band of oak which would fold around itself and up the wall, and cabinets would sit where gaps were left behind. The corners would be dovetailed to add tactility, and the interior of the cabinets would be spray coated in electric yellow.

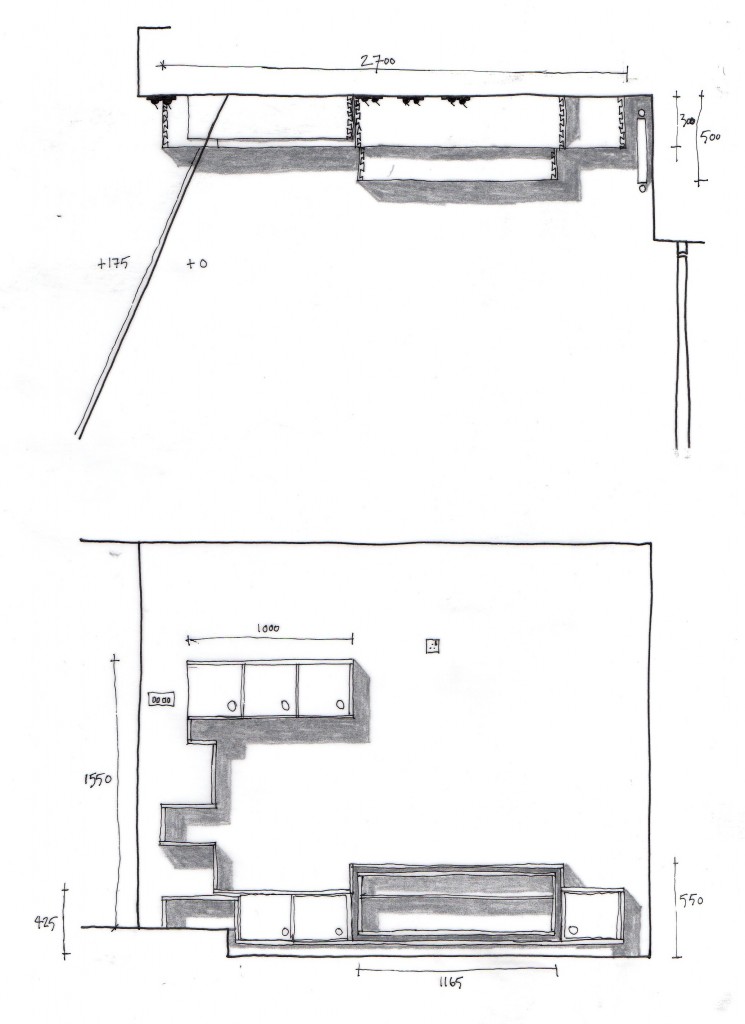

This was the initial design drawing prepared after the first meeting.

I was a little nervous about showing the clients the design, as I wasn’t sure whether it would be their style. Thankfully, they did, and virtually no changes were needed from this point on.

- There were a lot of components of varying sizes to be joined in this project, so after joining the board to make panels and cutting each to length, I laid out the design on the workshop floor to make sure it would all fit. The folded band of oak is quite clear in this image, and was one of the key concepts behind the design.

There is a deceptively large amount of timber in this piece, and every panel needed to be joined from two boards. This, and the dovetailing of each corner, took the lion share of the construction time. It’s really easy to miss a joint or cut a pin where there should be a tail, so every component was laid out in order and the joints were cut and fitted in sequence.

- Once the panels were cut to length, there were a lot of dovetails to cut. In order to ensure each piece was done correctly, I did them in order, and laid them back into place once cut.

After making sure all the dovetails fitted together, I started to assemble the piece. As it was to be fitted on-site, it was constructed in three sections – the bug eyes, the stem, and the base unit. The photo below shows the bug eyes being glued and clamped. All the cabinets were made with backs installed in order to provide a good fixing point for attaching the piece to the wall, and also so that the interior of the cabinets could be spray-painted at the workshop instead of needing to paint the wall once installed.

- The upper ‘bug eye’ cabinets, which inspired the name of the piece, being assembly. It’s quite a difficult operation, as the back panels have to be inserted when the dovetailed corner joints are together but not tight. You need about 10 hands, and it all gets a bit fraught as the glue starts to go off.

- The lower cabinet was glued and assembled in three stages to ensure all the panels were straight and the joints were tight. This photo shows when the cantilevered media storage section was inserted into the main body.

The media equipment storage part of the piece cantilevers out from the wall about 600mm. With all the electrical boxes on it, there’s quite a bit of weight. To counter this, it was attached to the body of the piece at two points underneath and again on top. Most importantly, it was screwed and plugged on the sides, to resist the twisting forces.

- Once assembled, the cabinets were oiled with 5 thin coats of finishing oil. The oiled sections were then covered up with newspaper prior to spray painting.

Oiling is always one of my favourite jobs because it’s when the grain of the timber really starts to sing. In this piece, it also brings the dovetail detail out. As you can see on the left of the image, the cabinet interiors are bare as they will be spray painted later.

- Before the electric green can be added to the cabinet interiors, the oak has to be undercoated. Paint doesn’t bond well to bare timber, so undercoating is essential for a good quality finish.

- The cabinet doors are made of moisture resistant MDF, and spray coated with satin grey paint. All the edges and corners are rounded which makes them more tactile but also helps the paint to coat uniformly and avoid forming drips.

Preparing the MDF for spraying is a laborious job. Each door needed to be cut to size and the pull handle formed. Then all the edges and corner were rounded to a 10mm radius with the router. This not only looks better, but also makes the job of painting that much easier as drips and chips are more easily avoided. The MDF must then be sealed with a couple of coats of PVA or the porous edges never coat properly with paint. It;s a good idea to use a specialist MDF undercoat as well. Although the grey might look a little dull here, it’s very classy when paired up with the natural oak in the finished piece.

- The cabinet interiors needed around 6 thin coats of the electric yellow paint, applied with a spray gun.

Spraying the electric green was a bit of a heart in mouth moment. The clients had chosen it specifically, and I really liked it, but you never know exactly what it’s going to look like until it’s done. I can imagine it’s not to everyone’s tastes, but I love it and I think it adds another unique feature to what is a one-of-a-kind piece.

The installation was quite straight forward and completed within a single day. The only challenge was avoiding the cables which sat behind the plasterboard. Luckily Kris, the client, was on hand to let me know where to avoid drilling. Here he is, mid-installation in the seat nook.

- Installing ‘The Bug’. It was brought to site in 3 pieces, but the dovetail jointed corners allowed for a quick installation.

During the making of this project, Lori gave birth to the couples’ second child, Zach. I know Lori didn’t much want to be in this picture, but it’s one of my favorites…

The finished project was selected to feature on an interiors website called bookcaseporn.com. Check out the link here…

- The finished piece, installed and in use. A big thank you to Kris and Lori for their commission and for being a joy to work with.

If you would like to see more fitted interiors and handmade furniture by Hugh, check out the HM HandMade website at www.hmhandmade.co.uk, or contact Hugh on 07789 768 302 or hugh@hmhandmade.co.uk.

Handmade Oak Fitted Furniture, Bespoke Hardwood Cabinetry, Handmade Living Room Furniture; Bespoke Solid Oak Fitted Furniture; Handmade Fitted Hardwood Living Room Furniture.